När man har slipat och lagt väv på insidan av däcket är äntligen alla de stora delarna klara. Och viktigast av allt, man behöver inte längre vara lika rädd för att träet ska röra på sig pga förändringar i temperatur och/eller luftfuktighet.

Rensa runt sittbrunnen..

Det kan vara lite knepigt att separera däck och skrov. Enklast är om man försöker skära rent glas eller kolfiber så fort epoxin har ”gellat” sig – väntar man tills den har härdat helt är det betydligt svårare och man riskerar skära ner i träet. Spanten får man knacka bort ett i taget så många man når via sittbrunn och luckor, och sen försiktigt bända loss hela däcket ute vid stävarna.

Därefter sågar jag rent och jämnar till med raspen lite runt sittbrunnen, samt skrapar bort alla rester av vit & smältlim.

Spackla

Eftersom det ligger kolfiber på utsidan kunde jag jobba bort mer trä på insidan utan att styrkan påverkas nämnvärt. Jag lånade min kompis Niklas överhandsfräs och körde bort 1-1,5 mm på det plana akterdäcket, medan en vinkelkap med grov slipskiva funkade bättre på fördäcket. Båda verktygen kräver stadig hand och starka nerver – typ; ”don’t try this at home” om du inte vet vad du sysslar med..

Slutfinish med oscillerande och sen nån timmes handjobb med 40 & 80-papper. Till sist grunda med epoxi och spackla hålkärl i alla fogar.

Glasfiber och kolremsor

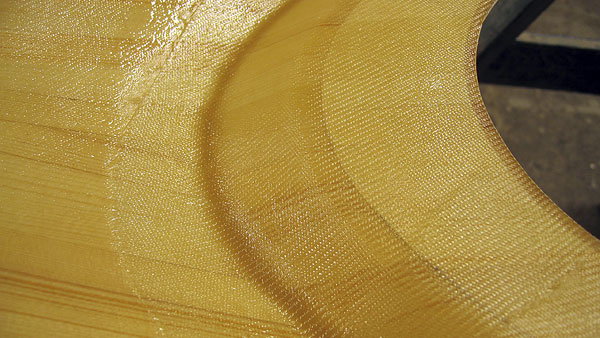

Sen lägger jag glasfibern – 163 g kring sittbrunnen och 80 g på resten. Dubbla lager runt själva nedsänkningen som extra förstärkning, och några remsor riktad kolfiber främst för att stadga upp akterdäcket.

Förstärkningar

Andra lagret epoxi

Klar insida

Dagen efter skär jag rent fibern, slipar till alla skarvar och lägger ett andra lager epoxi, främst på den tjockare väven och kolfibern. I ändskeppen räckte det bra med bara en strykning.

I själva sittbrunnen är det lite kinkigare så där brukar jag jobba noggrannare både med slipning & epoxi – det lär ju bli några timmars sittande här och då är det viktigt att man trivs ordentligt..!

Nästa steg..

Nu blir det sarg, sits och lite annat småplock, innan jag börjar med roder o styrsystem. Det känns som det värsta är gjort och hittills har det flutit på rätt ok. Peppar, peppar..

Innan månförmörkelsen

Tyvärr hade dom lovat mulet under månförmörkelsen under natten och på vägen hem hade diset redan börjat krypa in. Men det var en ganska stämningsfull promenad hem genom parken..

/ Ulf

fortfarande fint som attan!

Tummen upp! Snyggt jobbat!

Här kommer lite frågor:

-hur fäster du spanterna i skrovet? Såg på ett kort skymtar lite silverteijp. Är det allt?

-hörde någon säga att dessa nedsänkta luckor försvaga däckskonstruktionen. Men åt andra sidan finns det ju inte myckeet kvar av virket…..Vad säger du?

-du valde att ha ett platt akterdäck. Ett välvt däck är väl mera hållfast och vattnet rinner av bättre. Du kanske upplever detta inte som ett problem? Vad är dina synpunkter?

Ska ut nu på mitt andra träningspass idag (ganska ointressant….men även jag vill prestera bättre vid nästa DKM+)

Väntar med spänning på nästa uppdatering!

/Lars

Vilken bra byggblogg och så fina bilder!

Hej Lars!

När jag bygger däcket brukar jag sätta tillbaka spanten med några bitar silvertejp. Man får vara lite försiktig innan de första ribborna låser fast allt men sen brukar det faktiskt räcka, och eftersom jag när jag är klar måste vicka loss spanten inifrån vill jag inte fästa dem för mycket heller..

Alla hål i däcket försvagar men i o m att trä/epoxi-konstruktionen ändå är så överstark så har det nog ingen praktisk betydelse. I särklass största försvagningen är ju egentligen sittbrunnen och där bör man lägga det mesta krutet – ute i ändskeppen är krafterna mycket mindre. Delvis därför har jag både sarg och lucknedsänkningar i kol/glasfiber för att på så sätt få till starka ”ringar” att hålla ihop däcket med. Sen ger ju nedsänkningarna styrka på grund av ”vecken” också – se t ex bilplåt där man lägger in förstyvningsveck i huvar, dörrar mm.

Och ja, det platta däcket hade blivit mycket styvare som välvt – men det tyckte jag inte passade riktigt i formspråket (viktigt!).. Hoppas kolremsorna på undersidan håller det tillräckligt på plats (det är ju ändå en motionsbåt och dom brukar ju inte vara så styva i plasten..). Vattenavrinningen borde funka ok också – dessutom, den mesta delen av tiden torde vattnet, förhoppningsvis, först komma in över fördäcket. 🙂

Och då syns vi i Dalsland i sommar!

Erik A; Planen var lite att jobba in några moment i förväg för att sen kunna pytsa ut bilder i lugn och ro, men han Sivenbrantaren gick ju och skvallrade..

Erik S; Orange är faktiskt tävlingsfärgen som Laverda (ett av världens bästa motorcykelmärken någonsin..) hade på 70-talet..! Tyvärr är min SFC 1000 röd dock..

/ Ulf

Det brukar annarsgå bra att fästa spanten med smält lim,funkar även bra till limma nedsänkningar med små listbitar typ för sittbrunn och luckor